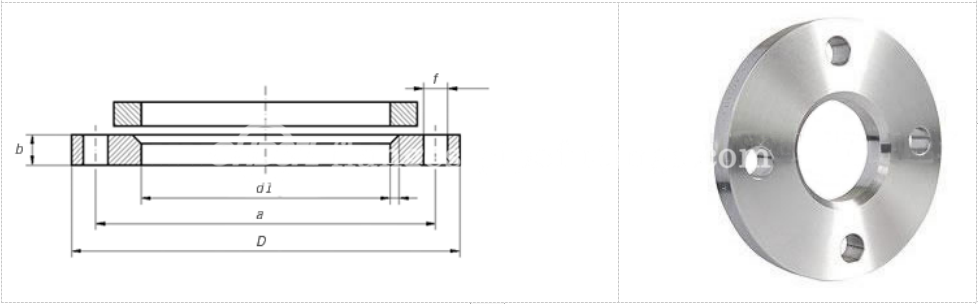

DIN 2642 PN10 FLANGE leupas

FLANGE LAPPED

Dimensi Flange & Beurat perkiraan

| Jérman baku flange DIN 2642 lapped flange;tekanan nominal 10 | |||||||||||

| Kalah Flansche Vorschweißbördel Glatte Bunde DIN 2642 Nenndruck 10 | |||||||||||

| Tournantes panganten awewe: nominal pression 10 | |||||||||||

| Pipa | Flange | Screws | Beurat | ||||||||

| Dipeunteun | d1 | D | d6 | b | k | e | liang | Benang | d2 | Kg | |

| ISO | DIN | ||||||||||

| 15 | - | 20 | 95 | 22 | 14 | 65 | 3 | 4 | M 12 | 14 | 0,689 |

| 21,3 | - | 24 | |||||||||

| 20 | - | 25 | 105 | 28 | 14 | 75 | 3 | 4 | M 12 | 14 | 0.806 |

| 26,9 | - | 30 | |||||||||

| 25 | - | 30 | 115 | 33 | 16 | 85 | 4 | 4 | M 12 | 14 | 1,11 |

| 33,7 | - | 36 | |||||||||

| 32 | - | 38 | 140 | 42 | 16 | 100 | 4 | 4 | M 16 | 18 | 1,64 |

| 42,4 | - | 46 | |||||||||

| 40 | - | 44,5 | 150 | 50 | 16 | 110 | 4 | 4 | M 16 | 18 | 1,86 |

| 48,3 | - | 54 | |||||||||

| 50 | - | 57 | 165 | 62 | 16 | 125 | 5 | 4 | M 16 | 18 | 2,20 |

| 60,3 | - | 65 | |||||||||

| 65 | 76,1 | - | 185 | 81 | 16 | 145 | 5 | 4 | M 16 | 18 | 2,62 |

| 80 | 88,9 | - | 200 | 94 | 18 | 160 | 5 | 8 | M 16 | 18 | 3,32 |

| 100 | - | 108 | 220 | 113 | 18 | 180 | 5 | 8 | M 16 | 18 | 3,67 |

| 114,3 | - | 119 | |||||||||

| 125 | - | 133 | 250 | 138 | 18 | 210 | 5 | 8 | M 16 | 18 | 4,54 |

| 139,7 | - | 145 | |||||||||

| 150 | - | 159 | 285 | 164 | 18 | 240 | 5 | 8 | M 20 | 22 | 5,60 |

| 168,3 | - | 173 | |||||||||

| 200 | 219,1 | - | 340 | 225 | 20 | 295 | 5 | 8 | M 20 | 22 | 7,46 |

| 250 | - | 267 | 395 | 273 | 22 | 350 | 5 | 12 | M 20 | 22 | 10,30 |

| 273 | - | 279 | |||||||||

| 300 | 323,9 | - | 445 | 329 | 26 | 400 | 5 | 12 | M 20 | 22 | 14.00 |

| 350 | 355,6 | - | 505 | 362 | 28 | 460 | 6 | 16 | M 20 | 22 | 18,50 |

| - | 368 | 374 | |||||||||

| 400 | 406,4 | - | 565 | 413 | 32 | 515 | 6 | 16 | M 24 | 26 | 25.00 |

| - | 419 | 426 | |||||||||

| (450) | 457 | - | 615 | 467 | 38 | 565 | 6 | 20 | M 24 | 26 | 30,60 |

| 500 | 508 | - | 670 | 517 | 38 | 620 | 6 | 20 | M 24 | 26 | 37.00 |

| 600 | 610 | - | 780 | 618 | 44 | 725 | 7 | 20 | M 27 | 30 | 56,30 |

| 700 | 711 | - | 895 | 721 | 50 | 840 | 7 | 24 | M 27 | 30 | 80,40 |

| 800 | 813 | - | 1015 | 824 | 56 | 950 | 7 | 24 | M 30 | 33 | 113,20 |

CATETAN:

1. Nyanghareupan nurutkeun DIN 2526

Beungeut datar:

Bentuk A, Beungeut tanpa syarat

Bentuk B, Beungeut Rz=160, dimesin (henteu leueur ti 40µm)

Beungeut diangkat:

Formulir C, Beungeut Rz=160, dimesin (henteu leueur ti 40µm)

Bentuk D, raray Rz = 40, machined

Bentuk E, raray Rz = 16, machined

2. Basa jeung alur nurutkeun DIN 2512

Wangun F, Basa

Bentuk N, alur

3. Jalu jeung Awéwé nurutkeun DIN 2513, DIN 2514

Bentuk V13, V14, Lalaki

Bentuk R13, R16, Awéwé

4. Chemfering pikeun diafragma-las packings, PN64-PN400, nurutkeun DIN 2695

5. Nyanghareupan pikeun sendi ngawangun lénsa, PN64-PN400, nurutkeun DIN 2696

Kapasitas Produksi & Rincian Meuli

1. Supply Flange Diménsi DN15 - DN2000 (1/2 "- 80", ngajalin Flange.

2. Bahan Karbon Steel: RST37.2, C22.8, S235JR, ST37, P235GH, P245GH, P250GH, ASTM A105

3. Bahan Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 jsb.

4. Flanges Anti Rust: Minyak Anti Rust, cet Hideung, Konéng cet palapis, Hot dipped Galvanized, Tiis Galvanized jsb.

5. Kaluaran Bulanan: 3000 ton per Bulan.

6. Sarat pangiriman: CIF, CFR, FOB, EXW.

7. Sarat pamayaran: Kawat Transfer (T / T), Irrevocable L / C dina Sight jsb.

8. Jumlah Orde Minimum: 1Ton atanapi 100Pcs.

9. Jaminan kualitas: EN10204 3.1 bijil, bijil Mill, Inspection pihak katilu, Service ngagantian bébas.

10. Manggihan More Sarat Dina Flanges Market.